[ad_1]

Whereas electrical autos are important to lowering carbon emissions, their manufacturing can precise a major human and environmental value. To run, EVs require six instances the mineral enter, by weight, of typical autos.

These minerals, together with cobalt, nickel, lithium and manganese, are finite resources. And mining and processing them may be dangerous for employees, their communities and the native atmosphere.

Projections present international EV gross sales surpassing gas-vehicle gross sales earlier than 2040.

The development is predicted to tremendously scale back emissions from transportation, which now characterize 14 p.c of the worldwide whole annually.

Because the demand for EVs rises, so will the demand for the minerals inside their batteries.

Your EV would possibly seem like a traditional sedan or SUV from the skin.

However beneath the ground of your automobile is an roughly 900-pound battery block containing supplies which have been mined from the bottom, despatched world wide and put by way of complicated chemical processing to gas your journey from level A to level B.

“In case you are going to check out any supply of power, you at all times can have some trade-offs,” mentioned Sergey Paltsev, a senior analysis scientist at MIT. “There is no such thing as a magic answer.”

Some of the frequent batteries on the highway, the NMC, utilized by firms together with Volkswagen, Mercedes and Nissan, comprises important quantities of aluminum, nickel, cobalt, manganese and lithium.

However whereas batteries might fluctuate in composition, they typically depend on the identical set of supplies.

[Quest for coveted EV battery metals yields misery in Guinea]

The place the minerals are

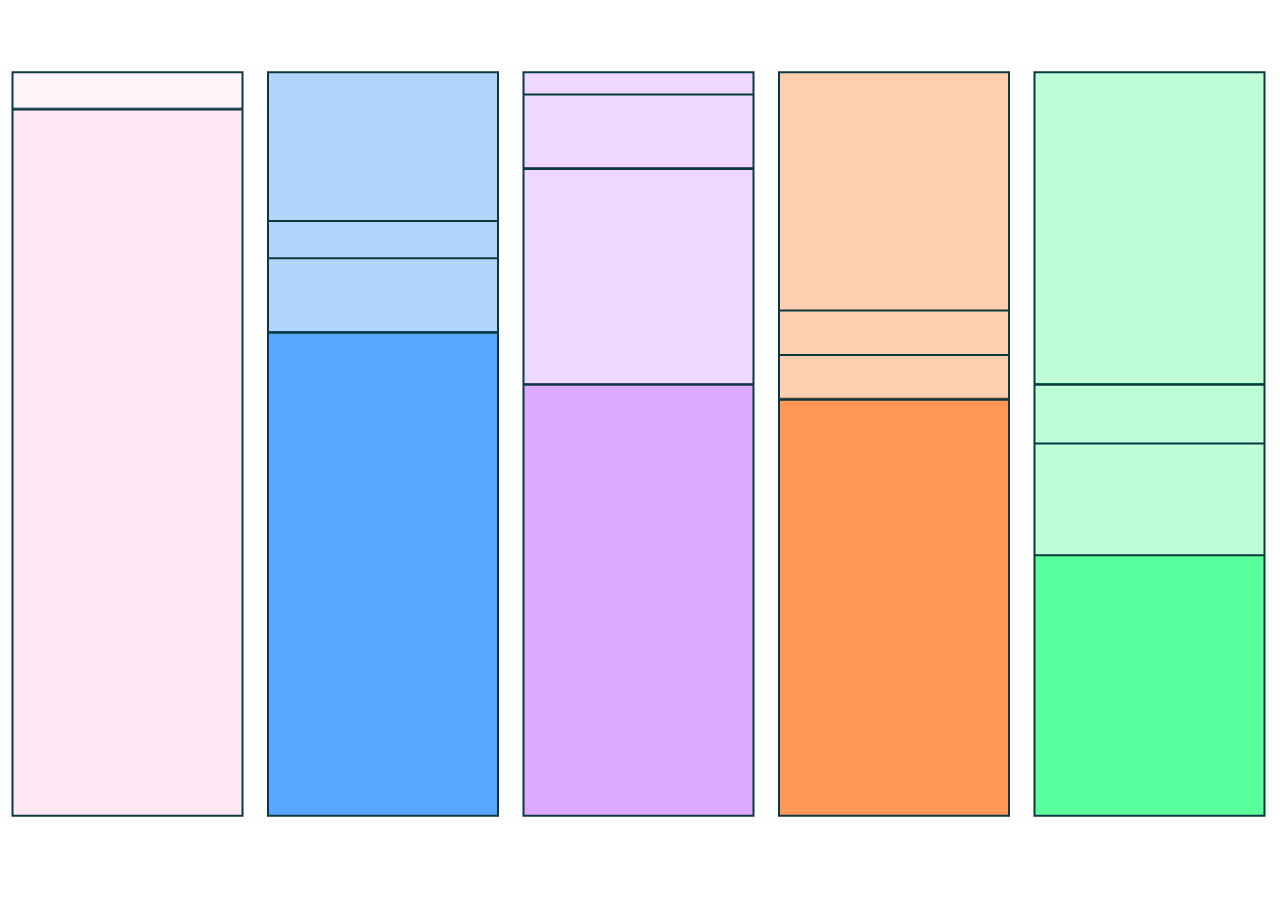

The 5 minerals most important to EV batteries are every concentrated in only a handful of nations. For these nations, the EV growth holds monumental financial promise, but in addition environmental, social and office challenges which have but to be addressed.

Bauxite

Prime bauxite-

producing nations

International locations with the

largest identified reserves

Guinea has 7.4B metric

tons of reserves, the

largest on this planet

Prime bauxite-

producing nations

International locations with the

largest identified reserves

Guinea has 7.4B metric tons

of reserves, the most important on this planet

Prime bauxite-producing nations

International locations with the most important identified reserves

Guinea has

7.4B metric tons

of reserves, the

largest on this planet

Prime bauxite-producing nations

International locations with the most important identified reserves

Guinea has

7.4B metric tons

of reserves, the

largest on this planet

Prime bauxite-producing nations

International locations with the most important identified reserves

Guinea has

7.4B metric tons

of reserves, the

largest on this planet

Manufacturing

Bauxite, a reddish rock that’s processed to provide aluminum, is generally mined in Australia, China and Guinea. The light-weight steel permits EVs to journey farther with out recharging than in the event that they have been manufactured from metal. Aluminum can be one of the vital important minerals in EV batteries.

Reserves

Guinea, one of many world’s poorest nations, sits on Earth’s largest bauxite reserves. By 2030, demand for aluminum will bounce practically 40 p.c, to 119 million tons yearly, industry analysts say. However the growth is taking a toll on the individuals who dwell on the land. Guinea’s authorities says tons of of sq. miles as soon as used for farming have been acquired by mining firms for his or her operations and related roads, railways and ports. Villagers have acquired little or no compensation, locals and rights activists say.

Nickel

Prime nickel-

producing nations

International locations with the

largest identified reserves

Indonesia is the highest producer of

nickel and has one of many largest

identified reserves on this planet

Prime nickel-

producing nations

International locations with the

largest identified reserves

Indonesia is the highest producer of

nickel and has one of many largest

identified reserves on this planet

Prime nickel-producing nations

International locations with the most important identified reserves

Indonesia is the highest producer of

nickel and has one of many largest

identified reserves on this planet

Prime nickel-producing nations

International locations with the most important identified reserves

Indonesia is the highest producer of

nickel and has one of many largest

identified reserves on this planet

Prime nickel-producing nations

International locations with the most important identified reserves

Indonesia is the highest producer of

nickel and has one of many largest

identified reserves on this planet

Manufacturing

Indonesia is the world’s prime miner of nickel by a wide margin, and if traits proceed, it’s going to produce greater than two-thirds of the worldwide nickel provide by 2030. International demand for nickel is predicted to extend practically 20-fold by 2040, and Indonesian officers have permitted the development of 9 new nickel smelters in an try and capitalize on the growth — with tariffs and export bans to maximise income at dwelling.

However native communities are petrified of the consequences of extraction and processing on their atmosphere.

Reserves

Sixty p.c of the world’s nickel reserves are concentrated in three nations: Indonesia, Australia and Brazil. China’s proximity to the nickel-rich nations within the South Pacific has introduced in overseas funding that may most likely drive development regardless of the environmental drawbacks.

Manganese

Prime manganese-

producing nations

International locations with the

largest identified reserves

South Africa is the world’s

prime producer of manganese

and has the most important identified

reserves

Prime manganese-

producing nations

International locations with the

largest identified reserves

South Africa is the world’s prime

producer of manganese

and has the most important identified

reserves

Prime manganese-producing nations

International locations with the most important identified reserves

South Africa is the world’s

prime producer of manganese

and has the most important identified

reserves

Prime manganese-producing nations

International locations with the most important identified reserves

South Africa is the world’s prime

producer of manganese

and has the most important identified

reserves

Prime manganese-producing nations

International locations with the most important identified reserves

South Africa is the world’s

prime producer of manganese

and has the most important identified

reserves

Manufacturing

South Africa’s mines produce greater than one-third of the world’s manganese provide, and analysts predict that international demand from the battery sector will improve ninefold over the following decade as EV suppliers use high-purity manganese to extend battery effectivity and scale back combustibility.

Employees in these mines say they’ve skilled reminiscence loss, slurred speech and different bodily impairments tied to ingesting the mineral’s effective mud.

Reserves

South Africa additionally sits on the world’s largest reserves of manganese. Ukraine has the fourth-largest identified reserves. One manganese basin rests within the nation’s south, which Russia continues to bombard in its invasion.

Lithium

Prime lithium-

producing nations

International locations with the

largest identified reserves

Afghanistan’s lithium

reserves might rival the

present largest identified

reserves in South America

Prime lithium-

producing nations

International locations with the

largest identified reserves

Afghanistan’s lithium

reserves might rival the

present largest identified

reserves in South America

Prime lithium-producing nations

International locations with the most important identified reserves

Afghanistan’s lithium

reserves might rival the

present largest identified

reserves in South America

Prime lithium-producing nations

International locations with the most important identified reserves

Afghanistan’s lithium

reserves might rival the

present largest identified

reserves in South America

Prime lithium-producing nations

International locations with the most important identified reserves

Afghanistan’s lithium

reserves might rival the

present largest identified

reserves in South America

Manufacturing

Lithium’s reactivity and lightness allow EVs to generate the identical power and pace as gas-powered autos. Demand for lithium is predicted to extend 40-fold by 2040, with 80 p.c of that demand pushed by EVs, in accordance with the Pure Assets Protection Council. Australia, Chile and China lead in lithium mining.

Reserves

Three of the most important present reserves are concentrated in South America’s “lithium triangle,” the place arid salt flats in Argentina, Bolivia and Chile make it straightforward to extract lithium by merely evaporating the basins’ brine water. Elevated lithium demand threatens to exhaust the area’s restricted water provide, displacing Indigenous communities and disrupting the delicate ecology.

There might quickly be one other provider. Afghanistan holds untapped lithium that will rival the world’s largest identified reserves. China has expressed curiosity in working with the Taliban authorities to faucet these reserves.

Cobalt

Prime cobalt-

producing nations

International locations with the

largest identified reserves

Democratic

Republic of Congo

The biggest identified

cobalt reserves are in

the Democratic Republic

of Congo

Prime cobalt- producing nations

International locations with the most important identified reserves

Democratic

Republic of Congo

The biggest identified

cobalt reserves are in

the Democratic Republic

of Congo

Prime cobalt-producing nations

International locations with the largest identified reserves

Democratic

Republic of Congo

The biggest identified

cobalt reserves are in

the Democratic Republic

of Congo

Prime cobalt-producing nations

International locations with the most important identified reserves

Democratic

Republic of Congo

The biggest identified

cobalt reserves are in

the Democratic Republic

of Congo

Prime cobalt-producing nations

International locations with the most important identified reserves

Democratic

Republic of Congo

The biggest identified

cobalt reserves are in

the Democratic Republic

of Congo

Manufacturing

Demand for cobalt is predicted to extend 20-fold by 2040.

Seventy p.c of the world’s cobalt is mined within the Democratic Republic of Congo. State-owned and Chinese language mining firms dominate the sector. However 15 p.c of Congo’s mining operations are within the casual sector, with greater than 200,000 folks working in unregulated and poorly ventilated mines.

The U.S. Labor Division estimates that between 5,000 and 35,000 youngsters, some as younger as 6, work in these unregulated operations.

Reserves

Congo can be sitting on the world’s largest reserves. As demand for cobalt rises, activists are calling for higher monitoring and regulation.

“Any actually moral response to this downside wouldn’t assist disengagement from [Congo] or contain the boycotts of its cobalt,” wrote Mark Dummet, the top of enterprise and human rights at Amnesty Worldwide. “As an alternative, what we, as activists, shoppers, auto makers, mining firms and governments alike have to be pushing for are sensible options that place human rights on the coronary heart of the power transition.”

China’s grip on the availability chain

Taking the minerals out of the bottom is simply step one. The ore is nearly by no means pure and must be refined, or processed, to turn out to be the minerals that go into batteries.

In relation to processing, there may be one main participant: China, which handles greater than half of the minerals vital to EV batteries. These parts aren’t used solely to energy EVs; in addition they seem in the whole lot from constructing supplies to toys. However because the demand for EV parts soars, so may dependency on China’s refining infrastructure.

% of minerals refined or processed

% of minerals refined or processed

% of minerals refined or processed

The US is making an attempt to develop its provide chain. The 2022 Inflation Discount Act gives a tax credit score of as much as $7,500 to shoppers below sure revenue ranges who purchase qualifying EVs. However starting in 2025, an EV that contains any minerals sourced or processed in China would not qualify for the total credit score. This poses an issue for cost-conscious shoppers, as Beijing controls the lion’s share of the world’s processing infrastructure, and 75 p.c of the world’s battery manufacturing capability, according to the International Energy Agency.

Within the quick time period, EV consumers might have hassle securing the tax credit designed to incentivize a clean-energy transition. However over time, such insurance policies may assist diversify the EV provide chain.

“We nonetheless are going to be depending on China for a lot of, a few years,” Paltsev mentioned.

correction

About this story

[ad_2]